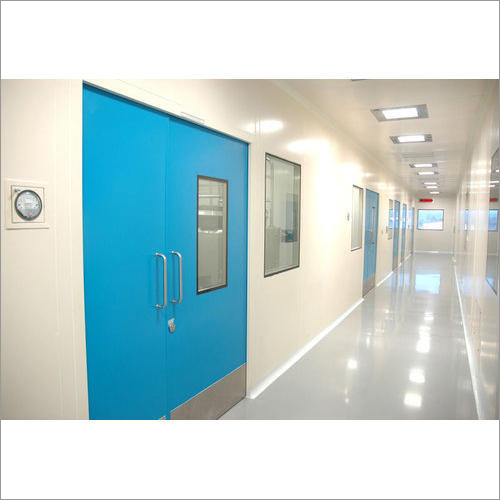

GI Operation Theater Clean Room Door

GI Operation Theater Clean Room Door Specification

- Dimension (L*W*H)

- 2100 x 1200 mm (Standard), Custom sizes available

- Feature

- Smooth, seamless finish; chemical and fire resistance; hermetic seal; easy clean design

- Thickness

- 50 mm to 70 mm

- Door

- Manual/Automatic (option available)

- Condition

- New

- Frame Material

- GI Powder-Coated Steel

- Air Flow

- Controlled (for cleanroom environments)

- Filter Type

- External (Connected to room systems)

- Filters

- Compatible with HEPA/ULPA room filtration

- Type

- Swing, Single/Double Leaf

- Application

- Operation Theater, Clean Room, Hospital, Pharmaceutical Units

- Floor

- Flush bottom with drop-down seal (optional)

- Weight

- Approx 45-60 kg per leaf

- Air Volume

- Dependent on room specification

- Lighting

- Vision panel with optional flush LED observation window

- Material

- Galvanized Iron (Powder-Coated)

- Fire Rating

- Available up to 60 minutes

- Glass Panel

- 5 mm toughened clear/opaque glass with rounded corners

- Gasketing

- EPDM/Silicon gaskets for airtightness

- Locking System

- Lever handle with lock, magnetic or mechanical

- Operation Panel

- Touchless activation/coded for automatic models

- Color Options

- Sky Blue, White, Green, Custom RAL Shades

- Insulation

- High density polyurethane/rock wool core

- Maintenance

- Low maintenance, easy to clean and service

- Surface Finish

- Antimicrobial powder coating

- Handle/Hardware

- SS304 lever handle, auto-closing hinges

- Hinges

- Heavy duty stainless steel, double ball bearing

- Sound Insulation

- Up to 35 dB reduction

GI Operation Theater Clean Room Door Trade Information

- Minimum Order Quantity

- 1 , , Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About GI Operation Theater Clean Room Door

Advanced Airtight and Hygienic Design

These clean room doors utilize EPDM or silicon gaskets for an exceptional airtight seal, minimizing air leakage and maintaining controlled environments. The antimicrobial powder coating and seamless finish help prevent microbial growth, supporting sterility protocols in operation theaters and pharmaceutical settings.

Customizable Options for Diverse Requirements

Select from a range of color finishesSky Blue, White, Green, or any RAL shadeto match your facilitys aesthetics. Available in standard or custom dimensions, with single or double leaf designs, and optional features like flush LED vision panels, these doors address specific operational needs without compromise.

FAQs of GI Operation Theater Clean Room Door:

Q: How does the GI Operation Theater Clean Room Door maintain a sterile and airtight environment?

A: The door is fitted with EPDM or silicon gaskets, creating a hermetic seal that restricts air and particulate movement. Its antimicrobial, powder-coated surface and seamless structure minimize contamination risks, while glass panels have rounded corners for easier cleaning.Q: What customization options are available for this clean room door?

A: You can choose from various color options, including Sky Blue, White, Green, or any custom RAL shade. The door is available in standard sizes (2100 x 1200 mm) or tailored dimensions, with single or double leaf configurations and clear or opaque glass panels. Additional features such as touchless controls or LED vision windows can also be included.Q: When should I consider using this GI clean room door in my facility?

A: These doors are ideal for environments where cleanliness, controlled air flow, and infection prevention are paramountsuch as operation theaters, clean rooms, hospitals, and pharmaceutical production areas.Q: Where can these clean room doors be installed?

A: They are suitable for hospitals, clean rooms, pharmaceutical units, laboratories, and any application requiring strict control over air and contamination.Q: What is the process for installing and maintaining these doors?

A: Installation is handled by experts to ensure a proper airtight fit. The doors are designed for easy cleaning and require minimal maintenance, thanks to their chemical resistance and robust hardware. Regular inspection and simple servicing keep them performing optimally.Q: How do the doors features benefit my operation?

A: With advanced fire resistance, sound insulation, airtight seals, and antimicrobial finishes, these doors enhance safety, privacy, infection control, and regulatory compliance in high-stakes environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Clean Room Door Category

Sliding Clean Room Door

Price 16000 INR / Number

Minimum Order Quantity : 10

Frame Material : Other, Aluminum / Stainless steel

Type : Other , Manual/Automatic Sliding

Application : Clean rooms, laboratories, pharmaceutical units, hospitals

Material : Other, Powdercoated galvanized steel / Stainless steel

Pharmaceuticals Clean Room Door

Price 222 INR / Square Foot

Minimum Order Quantity : 1 Foot

Frame Material : Other, Powder Coated Steel / Stainless Steel

Type : Other , Clean Room Door

Application : Pharmaceutical Clean Room

Material : Other, Galvanized Steel / Stainless Steel

Modular Clean Room Flush Door

Price nan INR

Minimum Order Quantity : na Square Meter

Frame Material : Aluminum

Type : Modular Clean Room

Application : G.i.Flush Door

Material : Other

Send Inquiry

Send Inquiry Send SMS

Send SMS